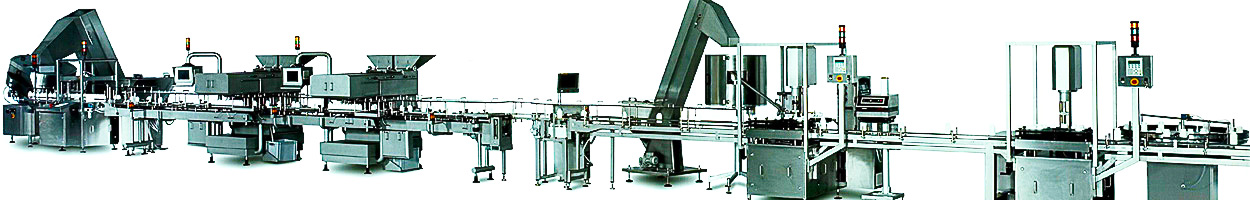

Machinery Safety Information

OSHA Safety Regulations for Industrial Machines and Equipment

ANSI Standards for Machines & Equipment

Overview

All Risk Assessment methods for industrial machinery do the following:Identify hazards Assess risk

Frequency of exposure Severity of possible injury Ability to avoid the hazard

Reduce risks Document results

For the 2010 release of ANSI B11.0 - Safety of Machinery, General Requirements and Risk Assessments, there is now a American National Standards Institute (ANSI) standard for performing risk assessments.

Recognizing a Hazard

Benefits

There are a number of major benefits of performing a Risk Assessment:It helps to meet all OSHA regulations and ANSI standards It provides a Cost Savings Significantly less risk of injuries to users Intangible Benefits

Cost Savings

Many people do not realize the significant cost savings that results from a carefully-performed Risk Assessment, but studies have repeatedly shown that a Risk Assessment save a company money. In particular, a study by Liberty Mutual showed that for every dollar spent on Safety and Risk Assessments, the company received 3 dollars worth of benefits.OSHA is even more positive about the benefits of Risk Assessments. According to OSHA’s office of Regulatory Affairs, every dollar spent on Safety saves a company $4 to $6.

Risk Assessment of a machine is the best single method to reduce the hazards, and to design a safe machine.

Results

The outcome of completing the risk assessment process should be:A clear understanding of risk(s) including the potential severity of harm and the probability of the occurrence of harm; Machinery with risks reduced to an acceptable level; Risk reduction measures appropriate to the circumstances; Documentation of the risk assessment.

It is strongly recommended that a Risk Assessment be performed in accordance with ANSI B11.0 - Safety of Machinery, General Requirements and Risk Assessments, as this is the best ANSI standard for Risk Assessments. It is also the method specified in ANSI B11.19 (2010) Performance Criteria for Safeguarding , which has become the de facto standard for machine safeguarding.

For training on Risk Assessments for machinery and equipment, see Risk Assessment Training

Training & Seminars

OSHA Training

Safety Training

Advanced, high-level training Customized to your machines On-site at your facility Personalized to your needs Taught by a machine safety expert

The most useful links, and the most helpful info for those using machinery and automated equipment.

The most useful links, and the most helpful info for those using machinery and automated equipment. There is a wealth of information within this site...

Useful Links

OSHA App: An iPhone app with all OSHA Regulations.

Expert Witness: An Expert in Machines, Manufacturing, and Automated Equipment.