Machinery Safety Information

OSHA Safety Regulations for Industrial Machines and Equipment

OSHA Regulations for Machine Guarding

Overview

OSHA's regulations for machine guarding are fairly generic -- however, they are wide reaching. There are, primarily, only three widely relevant OSHA regulations which cover machinery, industrial machine, and automation equipment. The three regulations are similar, but with subtle differences.These three OSHA regulations are (and I've highlighted the most critical part of each regulation):

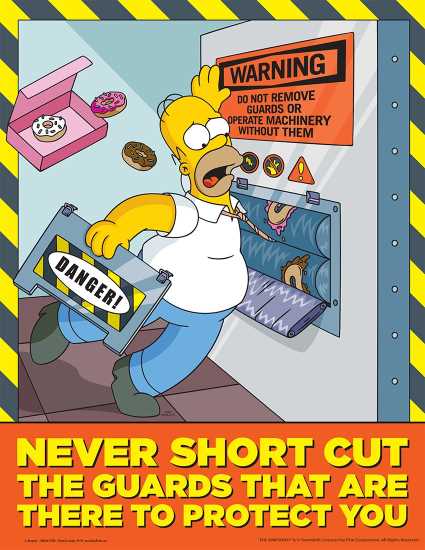

OSHA 1910.212(a)(1) Type of Guarding - One or more methods of machine guarding shall be provided to protect the operator and other employees in the machine area from hazards such as those created by point of operation, ingoing nip points, rotating parts, flying chips and sparks. Examples of guarding methods are-barrier guards, two-hand tripping devices, electronic safety devices, etc.With this regulation, OSHA requires that machine guarding be provided to protect the operators (and other employees) from all hazards. OSHA does not specifly which types of safeguards should be used, but includes several examples such as fixed guards, interlocked guards, light curtains, and other similar devices.

OSHA 1910.212(a)(2) General requirements for machine guards - Guards shall be affixed to the machine where possible and secured elsewhere if for any reason attachment to the machine is not possible. The guard shall be such that it does not offer an accident hazard in itself.With this regulations, OSHA requires that Machine guards be provided on all machines, and attached to the machine.

OSHA 1910.212 (a)(3) The point of operation of machines whose operation exposes an employee to injury, shall be guarded. The guarding device shall be in conformity with any appropriate standards therefore, or, in the absence of applicable specific standards, shall be so designed and constructed as to prevent the operator from having any part of his body in the danger zone during the operating cycle.With this regulations, OSHA requires that the guards be designed such that it is not possible to reach the hazard by reaching over, arround, under, or through the guard.

Further Information and Links

For ANSI standards on machinery and equipment guarding, see ANSI Standards for Machine GuardingFor training on OSHA and ANSI methods of machinery and equipment guarding, see: OSHA and ANSI Training

Training & Seminars

OSHA Training

Safety Training

Advanced, high-level training Customized to your machines On-site at your facility Personalized to your needs Taught by a machine safety expert

The most useful links, and the most helpful info for those using machinery and automated equipment.

The most useful links, and the most helpful info for those using machinery and automated equipment. There is a wealth of information within this site...

Useful Links

OSHA App: An iPhone app with all OSHA Regulations.

Expert Witness: An Expert in Machines, Manufacturing, and Automated Equipment.